Introduction

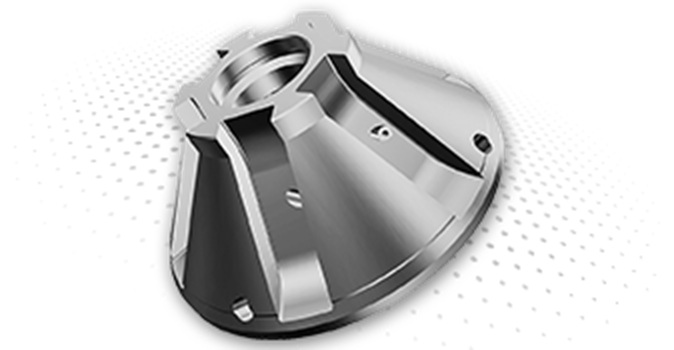

EZ-CAM 2025 introduces a comprehensive suite of enhancements designed to streamline CNC programming and improve machining efficiency. From a redesigned user interface to advanced toolpath options, this latest release emphasizes innovation, precision, and productivity. The integration of high-speed machining strategies, expanded import capabilities, and enhanced simulation controls sets a new standard for CAM software.

Redesigned Interface for Enhanced Usability

The user experience has been significantly upgraded with larger, visually optimized 32 x 32 command icons. These new icons enhance command recognition, reduce navigation time, and provide a cohesive and intuitive interface. This visual upgrade ensures that even complex operations are easy to access and execute.

EZ-MILL Toolpath Enhancements

- Seamless Pocket/Pool Operations

The new pathless pocket/pool feature enables handling open, closed, and undercut pockets within a single operation. This eliminates the need for multiple steps per pocket, vastly improving workflow efficiency. - Advanced Contour Wizard

- Slot/Dip/Top Radius Toolpaths: Optimized for circular and semi-circular slots, this feature automatically adjusts tool offsets to ensure precise center alignment, even when tool diameters vary from slot dimensions.

- 3D Chamfering: Enhanced for 3D edge processing, allowing faster and more accurate chamfering on complex geometries.

- Wall Stepping Toolpath

Supporting notch width and number settings, this toolpath type handles angled walls efficiently by dynamically adjusting Z-depth parameters for optimal material removal.

Ultra HSM Trochoidal Machining Innovations

High-Speed Machining (HSM) capabilities have been enhanced to ensure smoother entry and exit motions, safeguarding tool integrity and surface quality. The improved trochoidal strategy separates island machining into multiple sections, allowing for more efficient material removal, especially in complex geometries.

Surface Machining and Roughing Improvements

- Optimized 3D Roughing: With a 30% increase in toolpath calculation efficiency, users can now control lengthy processes via the ESC key, offering enhanced flexibility and control.

- Intelligent Toolpath Recall: If no parameters are changed, the system instantly recalls the last computed toolpath, drastically reducing redundant processing time.

Stock Management and Import Enhancements

- Alibre Integration

The new “Transfer Stock” command allows seamless transfer of models from Alibre to EZ-CAM as stock data, ensuring a smooth workflow. - Expanded Import Options

Users can now import IGES and STEP files as stock, fixture, or table models, in addition to STL, broadening compatibility with various CAD formats.

Simulation and Post-Processing Advancements

- Selective Simulation Start: Users can initiate simulations from any specific operation, skipping prior processes to focus only on relevant steps.

- Quick Post Output: A new context menu post command enables rapid generation and review of post-process files directly from the operation list.

Conclusion

EZ-CAM 2025 delivers a robust array of innovations designed to meet the evolving demands of modern CNC machining. From intuitive user interfaces to powerful machining strategies, this release empowers users to achieve unparalleled precision and efficiency.