What is Two-Photon Grayscale Lithography?

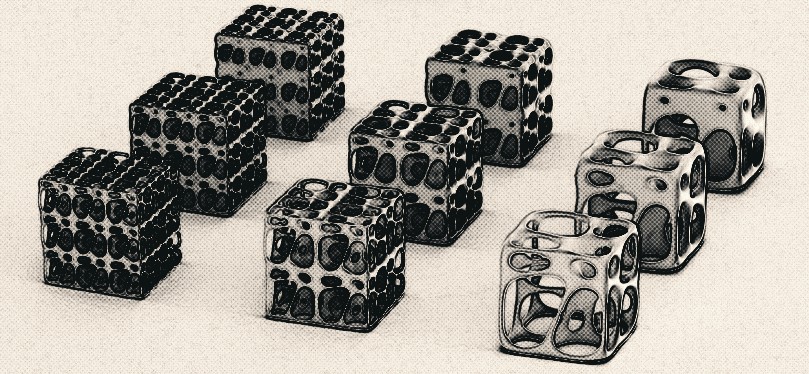

Two-Photon Grayscale Lithography has emerged as a groundbreaking innovation in industrial manufacturing and 3D printing technologies. This advanced technique leverages femtosecond laser pulses to create highly precise three-dimensional structures through an intricate polymerization process. The “grayscale” method further enhances this technology by varying the density of each voxel (volumetric pixel), enabling the production of incredibly detailed and precise 3D structures.

How Does It Work?

The technology operates by focusing a laser onto a specialized polymer material. The material hardens only at the point where two photons simultaneously interact with a molecule. This unique property facilitates the creation of nanoscale precision structures. The grayscale method allows for fine-tuning the density of each voxel on the material, providing unprecedented control over both structural and optical properties.

Advantages of Two-Photon Grayscale Lithography

- Unparalleled Precision: Achieves resolutions below 100 nanometers.

- Complex Geometries: Enables the creation of intricate 3D structures.

- Fast and Efficient Production: Saves significant time in industrial manufacturing processes.

- Versatile Applications: Can be applied across multiple industries.

Industrial Applications

- Micro and Nanotechnology:

- Microelectromechanical systems (MEMS).

- Micro-optic components such as lens arrays and waveguides.

- Medical Technology:

- Production of biomaterials and cell scaffolds.

- Development of microfluidic systems and biosensors.

- Aerospace and Defense:

- Lightweight yet durable microstructures.

- Optimization of optical systems for advanced defense technologies.

- Electronics and Photovoltaics:

- Manufacturing high-resolution circuit components.

- Surface coatings and thin-film technologies.

Integration with CAD/CAM

The integration of Two-Photon Grayscale Lithography with CAD/CAM software enables seamless production of complex designs. This compatibility has pushed the boundaries of 3D printing, making it an essential tool for industries such as automotive, aerospace, and medicine.

Frequently Asked Questions (FAQs)

- Which industries benefit from Two-Photon Grayscale Lithography?

The technology is widely used in microelectromechanical systems, medical technology, aerospace, defense, and electronics. - Why is it called “two-photon” lithography?

The material hardens only when two photons simultaneously strike a molecule, ensuring nanoscale precision. - How does this technology differ from traditional 3D printing?

Unlike conventional 3D printers, this technology achieves nanometer-level precision and allows for the control of optical properties. - What about the costs?

While more expensive for high-precision projects, its advantages make it a worthwhile long-term investment. - Who uses this technology?

Companies leading in micro and nanotechnology, as well as those in medical and defense sectors, extensively use this technology.

Future Expectations and Applications

Two-Photon Grayscale Lithography is poised to revolutionize industrial production and CAD/CAM applications. Its unparalleled precision, rapid production capabilities, and broad scope of applications make it an invaluable tool for future manufacturing. Companies looking to optimize their production processes can leverage advanced systems like Quantum X to stay ahead in the competitive landscape.

By bridging the gap between nanoscale engineering and industrial efficiency, this technology is set to play a pivotal role in shaping the next generation of high-precision manufacturing.