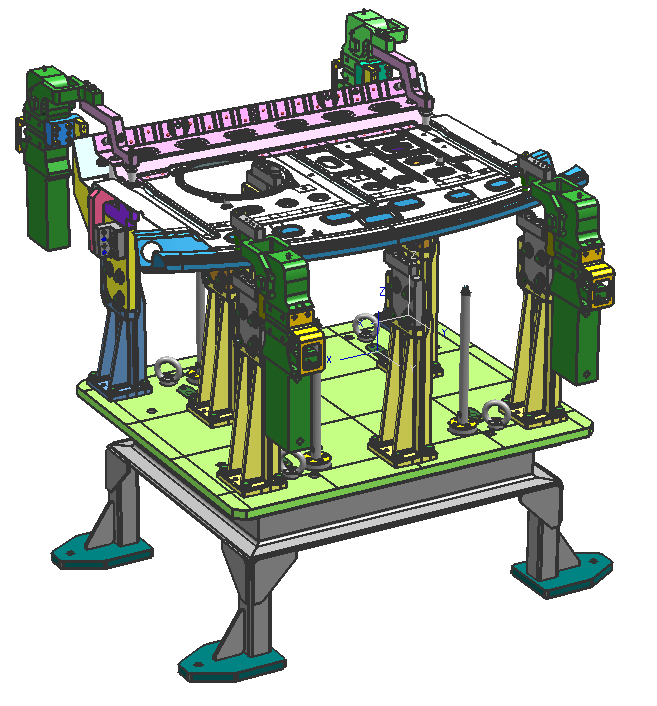

Welding fixtures are precision tools that hold components in place during welding processes to ensure accurate alignment and positioning. Their primary function is to enhance efficiency, accuracy, and safety in welding operations. Welding fixtures are essential for industries where precision is non-negotiable, such as automotive, aerospace, heavy machinery, and manufacturing.

Key Functions and Types of Welding Fixtures

- Positioning and Stability:

Welding fixtures securely hold complex components, ensuring they remain immobile during the welding process. This is crucial in high-precision industries like aerospace, where even minor misalignments can compromise structural integrity. - Types of Welding Fixtures:

- Modular Fixtures: Flexible and reconfigurable, these fixtures allow for quick adjustments, making them ideal for prototype development or low-volume production.

- Dedicated Fixtures: Custom-built for specific components or tasks, they offer unparalleled precision and are often used in high-volume manufacturing lines.

- Automated Fixtures: Integrated with robotic welding systems, these fixtures facilitate continuous production, enhancing speed and efficiency.

Applications in the Automotive Industry

The automotive sector is one of the largest users of welding fixtures. Vehicle chassis, frames, and other structural components are made up of numerous geometrically intricate sheet metal parts that require precise assembly. Welding fixtures ensure these parts are consistently aligned and securely joined, meeting stringent safety and quality standards.

For example, in robotic welding cells, fixtures work in tandem with robots to automate the welding of car body panels. This integration reduces human error, speeds up production, and maintains high-quality welds.

Benefits of Welding Fixtures in Manufacturing

- Increased Productivity:

By reducing the time needed to set up and align components, welding fixtures streamline the production process, enabling higher output. - Enhanced Quality Control:

Welding fixtures maintain consistent positioning and alignment, ensuring uniform weld quality across all products. This consistency is vital in industries such as aerospace, where weld integrity is critical. - Reduced Labor Costs:

With automated or semi-automated welding fixtures, manufacturers can reduce the need for skilled labor, lowering overall production costs. - Improved Worker Safety:

Fixtures minimize the need for manual handling of components during welding, reducing the risk of burns, injuries, or exposure to harmful fumes.

Innovations in Welding Fixture Technology

Recent advancements have introduced intelligent welding fixtures equipped with sensors and IoT integration. These fixtures can monitor welding conditions in real time, adjust positioning automatically, and provide feedback to operators, enhancing both precision and productivity.

Additionally, 3D-printed welding fixtures are gaining traction for their ability to produce complex, custom designs quickly and cost-effectively, making them ideal for small-batch production or prototypes.

Conclusion

Welding fixtures are indispensable in modern manufacturing, enabling the production of high-quality, complex components with precision and efficiency. Their role in industries like automotive and aerospace highlights their value in achieving consistent weld quality, reducing production costs, and enhancing workplace safety. As technology advances, welding fixtures will continue to evolve, offering even greater levels of automation, accuracy, and versatility.